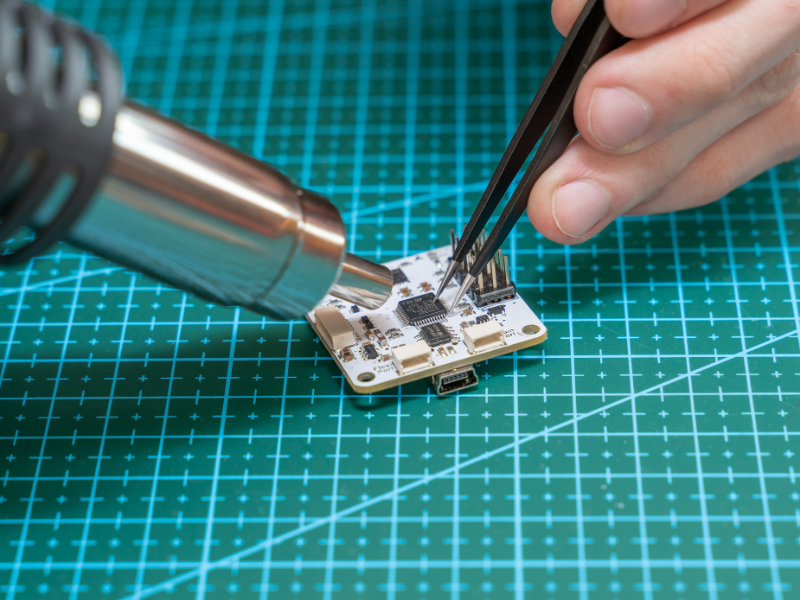

When the heat is not controlled properly many problems in electronics soldering happen. Sometimes parts on the board get damaged because they receive more heat than they should.

A soldering station helps to avoid these issues during work by fixing the correct temperature. It allows to set required heat level and maintain because the heat stays stable and solder melts evenly and forms stronger connections. This makes the process more reliable and reduces the need to resolder the solder joints.

When you handling small or sensitive electronic components. soldering station makes your work easy. The controlled heat protects the entire board from unnecessary damage. It helps to achieve best results and especially during long or repeated soldering tasks.

What is a Soldering Station

Soldering station provide controlled thermal energy to an electronic joint. It regulates temperature instead of running at constant power therefore It differs from a basic soldering iron. The control unit actively adjusts output based on feedback from the heating element, which keeps the tip close to the set temperature during use.

In most of the soldering stations include controller, hand piece and resting hand. The controller manages heat delivery, the handpiece transfers energy to the joint, and the stand protects the workspace. These elements create a system that supports repeatable soldering conditions.

Why a soldering station matters in electronics work

A soldering station is major because it eliminates thermal uncertainty from the process. When temperature remains stable, solder flows correctly, flux activates as expected, and joints solidify with uniform structure.

Unstable heat introduces defects. Operators compensate by holding the iron longer or increasing temperature, which stresses pads and nearby components. Over time, these habits increase failure rates and rework volume. A stable soldering station prevents that cycle by delivering heat only when and where it is needed.

In repair environments, controlled heat also reduces collateral damage.

Key factors to consider when choosing a soldering station

Temperature control and stability

Temperature control defines the quality of a soldering station. Electronics soldering operates within a narrow window, and the station must hold that range under load. When the tip contacts a joint, the controller should restore heat immediately without excessive fluctuation.

Stable control produces uniform joints and protects pads from thermal shock. It also allows operators to standardize procedures instead of adjusting technique for tool behavior.

Power rating and heating speed

Power rating is used to define the responsiveness of the station to thermal demand. Faster warm-up and constant performance are achieved with adequate power. when you are soldering large pads, connectors, or ground planes. The station responds quickly.

In daily operation, faster recovery reduces dwell time at the joint. Shorter contact time lowers stress on components and improves overall throughput.

Tip compatibility and variety

The soldering tip defines contact area and heat transfer. Different assemblies require different tip profiles, and a station should support a wide range of standard tips. Limited tip options restrict application range and slow work.

Tip availability also affects long-term ownership. Stations that use widely supported tips simplify maintenance and reduce downtime when replacements are required.

Safety features and ESD protection

Modern electronic components require protection from electrostatic discharge. An ESD-safe soldering station prevents latent failures that may not appear during initial testing. For any work involving ICs or surface-mount devices, ESD control should be treated as a baseline requirement.

Operator safety matters as well. Insulated handpieces, stable stands, and automatic sleep functions reduce burn risk and extend consumable life. These features support safe and predictable daily use.

Types of soldering stations for different applications

Different soldering tasks require different station designs. Understanding the main categories helps narrow selection.

Analog soldering stations

Analog soldering stations rely on manual temperature adjustment through simple control circuits. They offer durability and straightforward operation. While they lack digital feedback, many provide consistent performance for standard electronics work.

Training labs and basic assembly environments often use analog stations because of their simplicity and robustness.

Digital soldering stations

Digital soldering stations regulate temperature through microprocessor control. They display real-time temperature and respond quickly to load changes. This precision supports consistent results across operators and shifts.

Production lines, repair centers, and advanced prototyping environments commonly choose digital stations for their control accuracy.

Hot air and rework soldering stations

Hot air soldering stations support surface-mount assembly and rework. They apply controlled airflow to heat components evenly, which allows safe removal and installation on dense boards.

Rework stations often combine hot air tools with standard soldering irons. These systems support repair operations dealing with modern PCB layouts.

Common mistakes to avoid when selecting a soldering station

Many buyers prioritize initial cost over performance and stability. Low-cost stations often struggle with temperature control and component quality. Another common mistake involves ignoring tip ecosystem support, which becomes a problem during maintenance.

Some teams overlook ESD requirements or choose stations that do not fit their workspace layout. These decisions usually surface later as efficiency or reliability issues.

How the right soldering station improves work quality

The right soldering station improves work quality by enabling consistent execution. Operators apply heat confidently because the tool behaves predictably. Joints form correctly on the first pass, and inspection failures decrease.

As consistency improves, rework declines and throughput increases. The station supports the process instead of introducing variability.

Choosing the right soldering station for long-term use

A soldering station functions as a long-term asset. Build quality, spare part availability, and manufacturer support determine service life. Stations designed with modular components and standard consumables adapt better as requirements evolve.

Selecting a versatile station reduces replacement cycles and supports future application changes.

Conclusion

A soldering station shapes the outcome of every electronics assembly task. Temperature control, power response, and ergonomics directly affect reliability and efficiency. Choosing the right station strengthens process control and reduces avoidable defects.