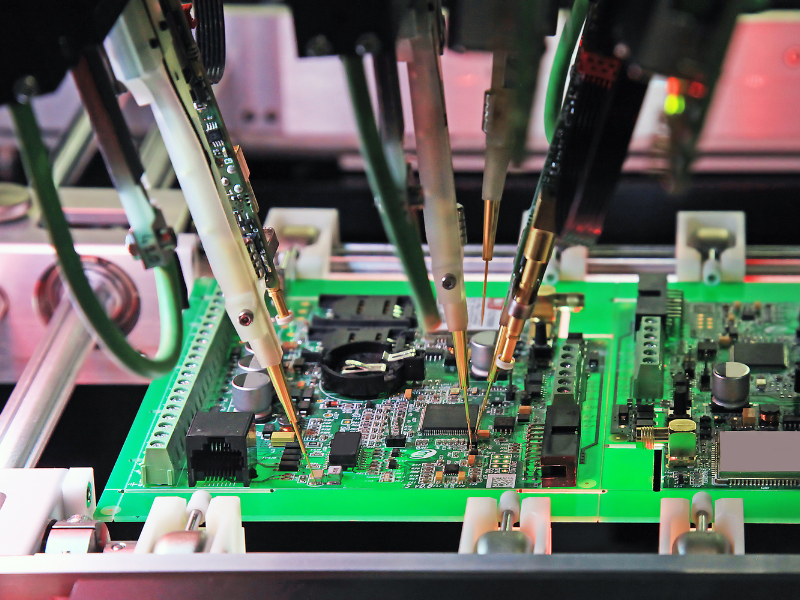

Electronic devices are present everywhere in this modern era. Whether it's a home or an industrial area. Everyone used them, but often observed that these devices malfunction over time. These devices run with various parts that support the overall system and one such component is the printed circuit board that are commonly known as a PCB.

When a PCB got fails during the work so their replacing can be more costly and time consuming. The right reworks tools help to solve the problems of malfunction PCB. This is where advanced PCB rework tools play a major role. These tools help technicians to repair and reuse damaged boards instead of throwing.

Understanding the Need for PCB Repair tools in Modern Electronics

Electronics parts are built with highly sensitive components. Whenever you repairing a PCB so make sure that a small mistake can damage the entire board. That is why advanced PCB rework tools are too much optional.

Saving Cost and Reducing Waste

Repairing a PCB is too much better option rather than buying a new one. Advanced rework tools helps technicians to fix specific faulty components instead of replacing the entire board. This approach helps companies to save lots of money and also reduces electronic waste.

Supporting Fast Repair Cycles

These PCB rework tools that accelerate the process of repair. Increased speed and accuracy in repairing goods means that production and service processes still proceed without significant interruptions.

Handling Advanced Technology

Advanced rework tools are designed to handle modern electronics without causing further damage rather than traditional tools are no longer sufficient because, today’s PCBs use fine pitch components and compact layouts.

Key Challenges in High-Density and Sensitive PCB Rework

Modern PCBs are more sensitive and costly they built with high accuracy therefore the challenges during rework also increase. There are many challenges that every technicians face due to repairing:-

Risk of Component Damage

High-density PCBs have very little space between components. High heat temperature can break or wrong handling can damage nearby parts. Advanced tools are needed to control them and accurate properly.

Thermal Control and Heat Sensitivity

One of the biggest challenges is manage temperature during the repairing of PCB. Modern PCBs contains tightly packed components which are highly sensitive to temperature variations. You should maintain the temperature to accurate and consistent control is essential for safe and effective rework.

Electrostatic Discharge Risks

Electrostatic discharge poses a serious threat to sensitive electronic components. Static electricity can damage integrated circuits without leaving visible signs. which can cause of delayed failures after the repair is completed.

Limited Access and Component Spacing

The space between components continues to decrease and PCB designs become smaller. This kind of accessibility restricts the removal and replacement of individual parts without interfering with other components around it. Such restricted areas need special tools and great care to operate in such restricted working environments.

Inspection and Visibility Challenges

Many modern PCB components are extremely small and difficult to inspect with the naked eye. There are many types of Soldering defects such as misalignment, and micro-level that are easily go unnoticed.

Static Electricity Issues

Sensitive electronic components can be damaged by static electricity without any visible sign. This makes ESD protection a serious challenge during PCB rework.

Visibility and Accuracy

During work many components are extremely small therefore they difficult to see clearly with the naked eye.

Core Advanced PCB Rework Tools Driving Innovation

Advanced PCB rework tools are shaping the future of electronics by making repairs safer, faster, and more reliable. These tools form the backbone of modern rework labs.

BGA Rework Stations for Complex and Fine-Pitch Components

BGA rework stations that are providing accurate temperature control and uniform heating which helps to remove and replace complex. This is the most advance rework tool that use in PCB repair. This designed to handle Ball Grid Array components. which are commonly used in modern electronics.

Precision Soldering Stations for Reliable PCB Repair

A good soldering station is major for any rework process it’s offer accurate temperature control to stable performance and consistent results. They reduce the risk of overheating strong solder joints and reduces the risk of overheating sensitive components.

Magnifying Lamps for Accurate Micro-Level Inspection

The small components clearly can be observed with the help of Magnifying lamps. This process reduces mistakes and make sure high-quality repair work.

Safety and Compliance Tools for Future Ready Rework Labs

A future ready rework lab does not only concentrate on the quality of repairs but also on safety and compliance. These instruments assist in the development of a controlled and professional working environment.

Fume Extractors for a Clean and Healthy Rework Environment

Whenever you working with Soldering and rework processes you noticed that there are many harmful fumes in your surround. Fume extractors remove these fumes from the workspace. This also protects the health of technicians and keeps clean the lab environment.

ESD Testers for Preventing Static Damage

ESD testers help verify to grounding systems that are working properly or not. They make sure that wrist straps, footwear, and workstations are safe to use. This prevents hidden damage caused by static electricity.

ESD Chairs and ESD Trolleys for Controlled Workspaces

ESD chairs and trolleys are designed to maintain proper grounding during work. They help technicians move safely and comfortably while handling sensitive PCBs. This creates a stable and controlled rework environment.

Process Quality and Cleanliness Tools in PCB Rework

Small Contaminant can affect soldering quality and performance therefore Cleanliness tools plays a major role in PCB rework.

Stencil Cleaning Rolls for Consistent Soldering Results

Stencil cleaning rolls help to remove extra solder paste and debris from stencils. This process improves the consistency and reduces defects during rework.

Solder Masks for PCB Protection and Repair Finishing

Solder masks protect PCB tracks and prevent solder bridges during repair that’s help restore the board original protection. This improve durability and gives a professional finish.

Supporting Tools That Improve Rework Speed and Efficiency

Supporting tools may not perform soldering directly, but they play an important role in improving efficiency and workflow.

Pneumatic Screwdrivers for Fast and Controlled Assembly

Pneumatic screwdrivers is used for quick and controlled fastening and unfastening of components. They save too much time rather than manual effort. It’s improve consistency during assembly and disassembly.

Resistance Meters for Testing and Verification

Resistance meters helps to verify electrical connections after repair. They make sure that the repaired PCB functions run properly. This step improves dependability and reduces the chances of future failure.

How Advanced PCB Rework Tools Improve Productivity and Reliability

Advanced rework tools help technicians to work faster without compromising on quality. It’s help to Accurate temperature control, proper safety measures, and better visibility that reduce rework errors.

Future Trends in PCB Rework Technology

The technology of PCB rework is developing. Smarter tools such as Automation, thermal control, and smarter inspection are literally defining the future. Modern Rework tools are now smarter and easier to use. It is moving towards the focus on the proper, safety, and sustainability.

Why Advanced PCB Rework Tools Matter for Long-Term Success

Advanced PCB rework tools is designed for long-term decision. These tools reduce waste, improve repair quality, and protect sensitive electronics. Firms that embrace the new rework systems remain competitive in the dynamic electronics market.

Conclusion: Building a Future-Ready PCB Rework Setup

High-end PCB rework devices are no longer a preserve of high-volume product manufacturers. They are becoming an essential part of every modern electronics laboratory. The combination of rework, safety, and support tools allows businesses to complete complicated repairs with ease. A rework facility that is future-ready will guarantee quality, efficiency, and sustainability in the modern electronic world.